When people consider installing a heat pump, the spotlight often falls on it only: it’s brand, technology, refrigerant, and advertised efficiency. However, the major factor determining how efficient a heat pump will be is the radiators it is connected to.

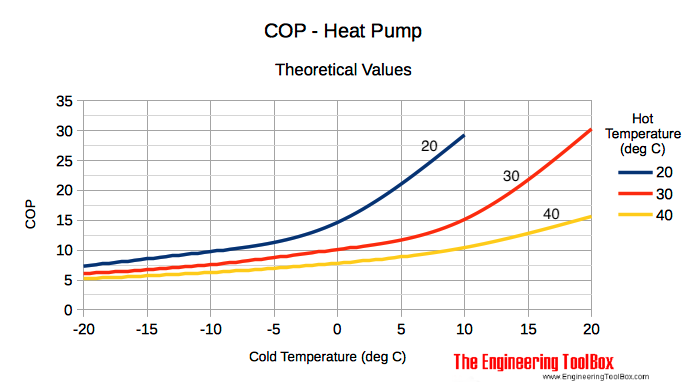

This is because a heat pump’s seasonal coefficient of performance (SCOP) — a measure of how much heat energy it can deliver compared to the electricity it consumes across a whole year — is highly sensitive to the temperatures it has to work at. Radiators directly dictate those temperatures. If the radiators are undersized, inefficient, or in poor condition, the heat pump will be forced to run hotter, and its SCOP will tumble.

Radiators and Flow Temperature

Radiators don’t produce heat; they “transfer” it. The larger the radiator surface area and the more efficient its design, the more heat it can emit at a given water temperature.

- A modern double-panel, double-convector radiator might emit the same heat at 45 °C water temperature as an older single-panel radiator would at 65 °C.

- If your home has lots of small, old radiators, the only way they can deliver enough warmth in mid-winter is if the water flowing through them is hot — often 60–70 °C. That’s fine for a gas boiler, which happily produces hot water at 70–80 °C, but a heat pump’s efficiency plummets when pushed above 50–55 °C.

The simplest way to allow a heat pump to run efficiently is to have more radiators. Each additional radiator adds emitting surface area, meaning the system can deliver the same heat to the home while running at a lower water temperature.

For example:

- Suppose a room needs 2 kW of heat on a cold day.

- One old single-panel radiator might only emit 2 kW at 65 °C water.

- Replace it with two modern radiators, each sized to deliver 1 kW at 45 °C, and the heat pump can now run at 45 °C flow instead of 65 °C. That could boost SCOP by 20–40% depending on climate.

Distribution across rooms

It’s not just total number that matters, but how they’re distributed. An oversized radiator in the living room won’t help if the bedrooms upstairs are freezing because they still have tiny 600 mm singles. Heat pump efficiency depends on being able to keep the whole home comfortable without raising flow temperature for one weak link.

Floor area vs radiator count

Larger homes naturally need more radiators. But many UK homes built in the 1960s–1990s were fitted with minimal radiator counts — just enough to keep a gas-boiler system adequate. Retrofitting for a heat pump often means increasing radiator numbers by 20–50%.

Panel size and surface area

The physical size of a radiator is the single most obvious determinant of its output at a given water temperature. Tall, wide, or deep radiators simply have more surface for air to contact.

- Single-panel radiators are the least powerful per length.

- Double-panel, single-convector (P+ type) add output.

- Double-panel, double-convector (K2 type) can deliver nearly three times the heat of a slim single.

- Triple-panel designs (K3) can achieve very high outputs at low temperatures, though they are bulky.

Low-temperature efficiency

Because heat pumps thrive at lower water temperatures, radiators need to be oversized relative to what a gas boiler required. A room that previously had one P+ might need a K2 or even two radiators at 45 °C design flow.

Vertical radiators

These have become fashionable, but many have less surface area than horizontal radiators of the same height. Unless carefully specified, they can be a liability for heat pump SCOP.

Radiator Efficiency Beyond Size

It’s not only surface area that matters. Design tweaks influence how effectively a radiator converts hot water into room heat.

- Convection fins: Modern convector plates welded between panels greatly boost airflow and heat transfer.

- Airflow patterns: Radiators placed under windows use rising warm air to counteract downdraughts; when moved to less effective positions, their practical efficiency drops.

- Active flow: Adding very low power fans to radiators increases airflow over a radiator’s surface at a negligible running cost. This enhances heat transfer by boosting the convection effect, helping distribute heat more evenly and quickly, even with lower water temperatures.

- Radiant vs convective balance: Most radiators are largely convective (heating air), but designs like cast iron or aluminium can emit more radiant heat, making rooms feel warmer at lower air temperatures.

High-efficiency radiators allow the heat pump to run cooler and keep SCOP higher.

The Condition of Radiators

Even the best-sized radiator can underperform if it’s in poor condition.

Sludge and corrosion

- Over years, central heating systems accumulate sludge (magnetite particles) and rust.

- This reduces water flow, creates cold spots, and slashes radiator output.

- A sludged-up radiator might deliver 20–40% less heat than its rating, forcing the heat pump to raise flow temperature to compensate.

Air trapped in radiators

Trapped air pockets reduce effective surface area. Regular bleeding is essential.

Fouling of fins

Dust clogging the convector fins under radiators impedes airflow and reduces output. A quick vacuum can measurably improve performance.

Valve performance

Old radiator valves may not open fully, restricting flow. Poor hydraulic balancing leads to some radiators running too cool while others hog flow, again pushing up system temperatures unnecessarily.

Keeping radiators clean, flushed, and balanced is a surprisingly powerful lever on SCOP.

Interaction with Heat Pump Control Strategy

Radiators and controls work together.

- Weather compensation: A heat pump can automatically vary flow temperature based on outdoor temperature. With adequately sized radiators, weather compensation keeps flow very low in spring/autumn, giving spectacular COP figures.

- Constant low-flow operation: Radiators designed for continuous low-temperature heat work best with heat pumps. Stop-start control or undersized emitters undermine this.

- Zoning pitfalls: Shutting down too many radiators (e.g. only heating one room) can reduce flow volume through the system, making it harder for the heat pump to modulate efficiently.

Practical Examples of Radiator Impact on SCOP

Let’s take a worked example to see how radiator capacity alters SCOP.

- A typical 3-bed UK semi requires ~8 kW peak heat load at −3 °C outdoor temperature.

Case A: Old boiler radiators

- Existing system: 7 single-panel radiators sized for 70 °C flow.

- At 45 °C flow they can only emit 4 kW.

- Heat pump must run at 60 °C+ to keep house warm.

- Average SCOP over winter: ~2.7.

Case B: Upgraded radiators

- Replaced with 11 double-panel convectors sized for 45 °C design.

- Heat pump runs at 45 °C most of winter.

- Average SCOP: ~3.8–4.0.

Case C: Oversized radiators

- 14 radiators, all K2 or K3 types.

- Design temperature 35 °C.

- Heat pump SCOP: 4.5–4.7, with some days reaching instantaneous COP above 5.

A difference in running cost between Case A and Case C could be £400–£600 per year for the same house, plus lower CO2 emissions.